Contact us for help?

Contact with us through our representative or submit a business inquiry online.

.

ACOUSTIC EMISSION TESTING (AET)

Acoustic Emission Testing Singapore is a Non-Destructive Testing (NDT) method that is used to analyze emitted sound waves caused by defects or discontinuities. These acoustic waves are induced by small deformations, corrosion, or cracking, which occur prior to

APPLICATIONS OF ACOUSTIC EMISSION TESTING (AET)

Storage tank Bottom floor inspection / Full Integrity Testing

No need to evacuate the load from the storage tank

Pressure vessels, Gas Bottles Integrity Testing without evacuating load

TRACK RECORD

Storage Tank Floor Bottom Inspection

FRP vessels

PERSONNEL QUALIFICATIONS FOR ACOUSTIC EMISSION TESTING (AET)

ASNT Level 2/3

LONG RANGE UT (LRUT) / GUIDED WAVE ULTRASONIC TESTING

APPLICATIONS OF LONG RANGE UT (LRUT)

Corrosion, Pitting in Insulated Pipelines

Corrosion, Pitting Buried Underground Pipeline

Process Pipelines Corrosion Findings

No need to remove insulations

No need to excavate full length of pipes

PERSONNEL QUALIFICATIONS FOR LONG RANGE UT (LRUT)

NDT Level II

TRACK RECORDS:

VOPAK Terminal

SembCorp

REAL TIME RADIOGRAPHY (OPEN VISION)

OpenVisionTM is a light weight live video X-ray imaging system specifically designed for hand-held inspection. It includes a highly sensitive radiographic imager and battery-operated 70kV x-ray tube designed for portable field operation. The proprietary intensified video imaging system captures images and displays them on a hand held LCD viewer, head mounted display, or portable recorder with LCD display in real-time.

APPLICATIONS

Corrosion Under Insulation on Piping

Geveral Visual Inspection Under Insulated Pipes

TRACK RECORDS

Shell Eastern Petroleum, Shell Bukom, Singapore

Exxon Mobil

EMAS Offshore

CORROSION UNDER INSULATION (CUI)

Corrosion under insulation (CUI) is the corrosion of piping and vessels that occurs beneath insulation as a result of water penetration. The water can come from rain water, leakage, deluge system water, wash water, or sweating from temperature cycling or low temperature operation such as refrigeration units.

INSPECTION METHODS

Long Range UT

Computed Radiography (CRT)

Digital Radiography (DRT)

Profile Radiography

Real Time Radiography (Open Vision)

PERSONNEL QUALIFICATIONS

API Piping Inspector (API 570)

TRACK RECORD

Exxom Mobil (Open Vision)

Shell Eastern Petroleum, Bukom Terminal (Open Vision, Profile Radiography

MISC Malaysia (Computed Radiography)

PROFILE RADIOGRAPHY

Profile Radiography, technically called Tangential radiography is a radiographic

INSPECTION METHODS

Conventional Gamma Radiography

Conventional X-Radiography

Digital Radiography (DRT)

Computed Radiography (CRT)

PERSONNEL QUALIFICATIONS

API Piping Inspector (API 570)

TRACK RECORD

Shell Eastern Petroleum, Bukom Terminal (Open Vision, Profile Radiography

MISC Malaysia (Computed Radiography)

HIGH TEMPERATURE PHASED ARRAY ULTRASONIC TESTING (PAUT)

FEATURES

Phased array inspections at temperature up to 200°C

No shut down required while performing weld inspections and corrosion mapping

Automated scanning limits direct contact with parts at elevated temperatures

Encoded automated and manual scanning for consistency and repeatability

Multiple wedge sizes available for various wall thicknesses

Cooling systems prevent damage to the scanner, wedge and probe

COMPANY’S CREDENTIALS/APPROVALS/ACCREDITATION

IS/IEC – 17025

DNV Validation Approval for Piping

DNV Validation Approval for Structural

SAC-SINGLAS

PERSONNEL QUALIFICATIONS

Shell Eastern Petroleum for PEC 2014 Turn Around

HIGH TEMPERATURE UT THICKNESS GAUGING

Although most ultrasonic flaw detection and thickness gaging is performed at normal environmental temperatures, there are many situations where it is necessary to test a

APPLICATIONS

Petro chemical and process industries – Pre Shutdown & Maintenance

COMPANY’S CREDENTIALS/APPROVALS/ACCREDITATION

IS/IEC – 17025

SAC-SINGLAS

PERSONNEL QUALIFICATIONS

NDT Level II

CRAWLER UT GAUGING

Battery operated, encoded crawler with 5 MHz, dry coupled wheel probe. Supplied with a 50 metre umbilical cable for access to the top of the highest storage tanks methods. The Scorpion is a rugged remote access ultrasonic (UT) crawler designed for cost effective ultrasonic inspection on ferro-magnetic structures such as storage tanks, vessels and offshore installations without the need for costly scaffolding or rope access associated with UT thickness gauging.

APPLICATIONS

Tank Thickness Gauging without Rope Access / Scaffolding

Pressure vessels and offshore installations Thickness Gauging

PERSONNEL QUALIFICATIONS

PCN, PED, ISO 9712, EN 473, ASNT Level 2/3

High resolution B-scan image

Simple profile, or full amplitude display

Permanently stored data for recall to assist with RLA & RBI trend forecasting

No couplant or paint removal required

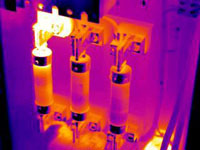

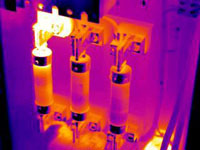

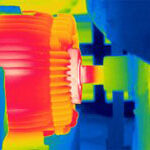

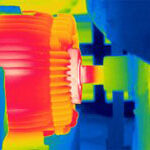

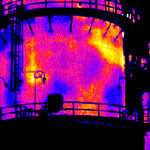

INFRARED THERMOGRAPHY

IR Thermography is based on the concept that, the object which has absorbed heat or at some temperature value higher than the ambient or surrounding environment will emit infrared radiation (heat flux) at different wavelength. The IR thermography method uses a thermal image scanner or camera to record the heat flux which was emitted as infrared radiation. The thermal image describes the distribution of the surface temperature that will detect the defects in the subsurface of the material tested. Because of different thermal coefficients between the sample surface and the ambient, the heat will flow in different ways (thermal wavelength) and also at different rates and thus results in a different temperature distribution on the surface of the sample with respect to the defects in the tested material.

IR Thermography has two different approaches namely passive and active, depending on how thermal load is applied to the object to be tested.

In passive approach, test samples are naturally at a higher temperature than the ambient whereas in active approach, an external stimulus is necessary to apply thermal contrasts to the test material. In active thermography, test materials are to be heated above the ambient temperature. It can be applied in two methods, single sided and double-sided. In single-sided, the sample will be heated first and afterwards heat release will be recorded by the thermal image scanner, while in the case of double sided, thermal image scanner and heat source are placed on opposite sides with respect to the sample and the scanner is switched on simultaneously with the heat source.

Applications:

Electrical Systems (faulty electrical or overloaded circuits)

Mechanical Equipment (abnormal warm motors and bearing failures)

Fluid Systems (line blockages, pipe or fluid temperatures, tank levels)

Building Applications (insulation defects, air infiltration, moisture defects)

Low-Slope Roofs (identify wet roof insulation)

In pulsed thermography method, the stimulation time will be less for higher thermal conductivity material and more for low thermal conductivity material. In this method initially the test material is heated and the thermal images are recorded during cooling cycle at regular intervals of time.