Advanced High Temperature Phased Array Ultrasonic Testing (PAUT) At A-Star Testing & Inspection Pte Ltd

A-Star Testing & Inspection Pte Ltd is at the forefront of providing innovative solutions in the field of non-destructive testing (NDT). Among their advanced offerings is the high-temperature phased array ultrasonic testing (PAUT), specifically designed to address the challenges of inspecting materials and welds at elevated temperatures. This cutting-edge technique is essential for industries where safety, reliability, and operational efficiency are paramount.

What is Phased Array Ultrasonic Testing (PAUT)?

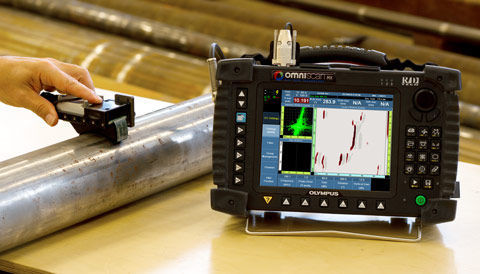

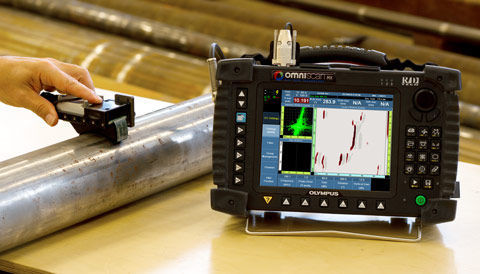

Phased array ultrasonic testing (PAUT) is a sophisticated NDT method that uses multiple small ultrasonic elements in a probe. Each element is individually pulsed with computer-calculated timing, allowing the ultrasonic beam to be electronically steered, focused, and swept across the test piece without physically moving the probe. This differs significantly from traditional single-element probes, which require physical movement to scan larger areas.

High-Temperature PAUT Capabilities

A-Star’s high-temperature PAUT systems are engineered to operate at temperatures up to 200°C, making them ideal for environments where elevated temperatures are the norm. This capability is crucial for industries such as petrochemical, power generation, and manufacturing, where downtime for inspections can be costly and disruptive.

Key Features of High-Temperature PAUT:

Temperature Resilience: Designed to perform inspections at temperatures up to 200°C, reducing the need for shutdowns during critical operations.

Automated Scanning: Utilizes automated scanning techniques to limit direct contact with hot surfaces, enhancing safety and inspection accuracy.

Encoded Scanning: Provides consistency and repeatability in inspections, ensuring reliable data collection.

Versatile Wedge Sizes: Available in multiple sizes to accommodate various wall thicknesses, allowing for flexible and comprehensive inspections.

Cooling Systems: Integrated cooling systems protect the scanner, wedge, and probe from heat damage, ensuring durability and longevity.

Applications and Advantages

High-temperature PAUT is particularly effective for:

Corrosion Mapping: Identifying and mapping corrosion at elevated temperatures without halting operations.

Weld Inspections: Conducting thorough weld inspections to detect flaws and ensure structural integrity.

Piping and Structural Inspections: Validated by DNV for both piping and structural applications, ensuring compliance with stringent industry standards.

The benefits of high-temperature PAUT include minimized downtime, enhanced safety, and precise defect detection. This makes it a preferred choice for industries where operational continuity and safety are critical.

A-Star Testing & Inspection Credentials

A-Star Testing & Inspection Pte Ltd is accredited and validated by several industry standards, ensuring the highest level of service and reliability:

IS/IEC – 17025: Accreditation for laboratory competence.

DNV Validation Approvals: Recognized for piping and structural inspections.

SAC-SINGLAS: Singapore Accreditation Council – Singapore Laboratory Accreditation Scheme.

Expertise and Experience

With over 20 years of experience, A-Star’s technical team is highly qualified and adept at handling complex inspection scenarios. Their credentials include notable projects such as the Shell Eastern Petroleum PEC 2014 Turn Around, demonstrating their capability to manage large-scale and high-stakes inspections.

Contact Information

For more information about A-Star Testing & Inspection Pte Ltd’s high-temperature PAUT services, you can reach them at:

Address: No.5 Soon Lee Street, #03-36/37 Pioneer Point, Singapore 627607.

Phone: (+65) 6261 6162, (+65) 6950 8325

Email: enquiry@astartesting.com.sg

Website: www.astartesting.com.sg | www.astartesting.co.in

A-Star Testing & Inspection Pte Ltd is committed to providing state-of-the-art NDT solutions to meet the rigorous demands of modern industries. Their high-temperature PAUT services ensure safety, efficiency, and compliance, setting the standard for excellence in non-destructive testing.